The Essential Guide to Barcode Label Ribbon for Your Business

In today's fast-paced and technology-driven business environment, the importance of accurate inventory management cannot be overstated. One critical component of effective inventory management is the use of barcode label ribbons. These ribbons not only facilitate the printing of barcodes but also play a significant role in ensuring that your business operations run smoothly. In this comprehensive guide, we will explore various aspects of barcode label ribbons, their benefits, types, and best practices that can help your business thrive.

What is a Barcode Label Ribbon?

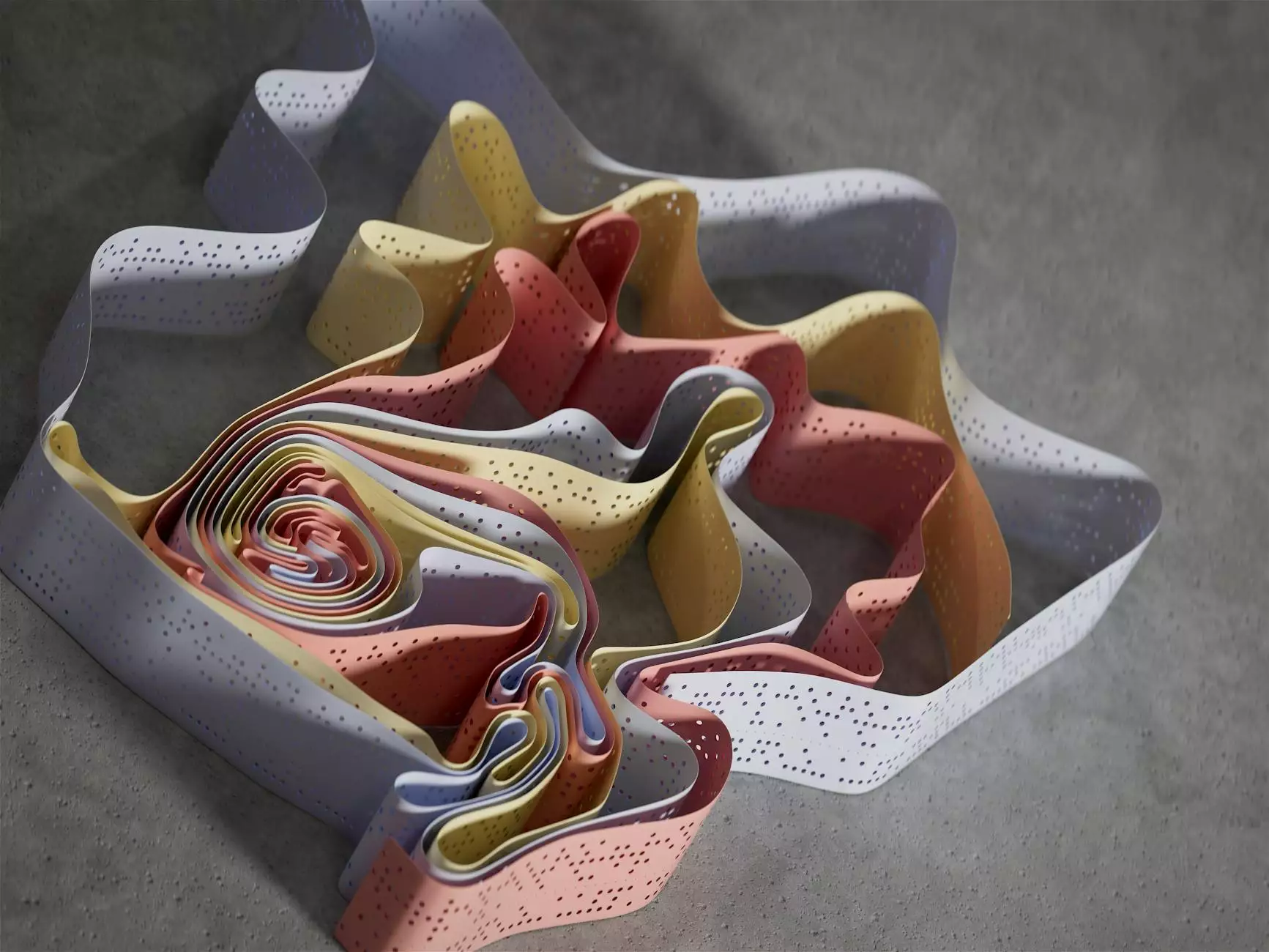

A barcode label ribbon is a crucial component in the printing of barcode labels. These ribbons are typically made from a thin film coated with a layer of wax, resin, or a combination of both. When heat is applied during the printing process, the ribbon transfers ink onto the label, creating a clear and scannable barcode. This process is primarily used in thermal transfer printers, which offer enhanced durability and longevity compared to direct thermal printing methods.

Types of Barcode Label Ribbons

Understanding the different types of barcode label ribbons available is essential for selecting the right one for your printing needs. Here are the main types:

- Wax Ribbons: These ribbons are ideal for printing on paper labels and are cost-effective. They provide good quality prints but are not suitable for high-temperature or high-friction environments.

- Resin Ribbons: Made from a more robust material, resin ribbons are designed for use on synthetic label materials. They offer high resistance to scratches, chemicals, and extreme temperatures, making them suitable for demanding applications.

- Wax-Resin Ribbons: Combining the best features of wax and resin, these ribbons offer excellent print quality and durability. They are versatile and can be used for both paper and synthetic labels, making them a popular choice for various business applications.

Benefits of Using Barcode Label Ribbons

Incorporating barcode label ribbons into your business operations can yield numerous advantages. Here are some notable benefits:

- Improved Inventory Management: By utilizing barcode labels printed with quality ribbons, businesses can efficiently track inventory levels, reduce errors, and simplify the restocking process.

- Enhanced Accuracy: Barcodes minimize human error in data entry, ensuring that the right products are delivered to customers.

- Cost Efficiency: Using high-quality barcode label ribbons can reduce printing costs over time, as they often produce more labels per roll than lesser quality products.

- Increased Productivity: Automating the inventory system through barcode scanning increases the speed at which items are processed, leading to faster customer service and improved workflow.

How to Choose the Right Barcode Label Ribbon

Choosing the right barcode label ribbon is essential for achieving optimal printing results. Here’s a step-by-step guide:

- Understand Your Label Material: Determine if you are printing on paper or synthetic labels, as this affects the type of ribbon needed.

- Evaluate Your Application Environment: Consider where the labels will be used. If exposed to harsh conditions, opt for resin or wax-resin ribbons.

- Check Printer Compatibility: Ensure that the ribbons you choose are compatible with your printer model for optimum performance.

- Analyze Print Volume: Assess your printing needs to determine the ribbon size and type based on the expected volume.

Best Practices for Using Barcode Label Ribbons

To maximize the performance of barcode label ribbons, follow these best practices:

- Store Properly: Keep the ribbons in a cool, dry place to avoid degradation caused by heat or humidity.

- Adjust Printer Settings: Make sure to set the printer to the correct temperature and speed to allow proper ink transfer.

- Regular Maintenance: Conduct routine maintenance on your printers to ensure optimal performance and prolong the life of the ribbons.

- Test Before Full Use: Always run test prints to verify the quality and durability of the labels before implementing them in your operations.

Popular Applications of Barcode Label Ribbons

Barcode labels printed with the right ribbons have a wide range of applications across numerous industries:

- Retail: Used for product labeling, stock management, and price tagging.

- Logistics and Shipping: Essential for tracking shipments, ensuring accurate deliveries, and managing warehouse inventories.

- Healthcare: Vital in patient identification, medication management, and laboratory specimen tracking.

- Manufacturing: Used for tracking parts and products throughout the manufacturing process.

- Food and Beverage: Helps in compliance with labeling regulations and tracking perishable items.

Conclusion

In conclusion, the role of barcode label ribbons in modern business practices is invaluable. With their ability to improve efficiency, increase accuracy, and support inventory management, incorporating the right barcode label ribbons into your business operations can significantly impact your bottom line. By understanding the different types of ribbons, their benefits, and following best practices, you can ensure your business remains competitive in today's marketplace.

For businesses looking to upgrade their printing services or explore the latest in electronics and computers, turn to Omega Brand for innovative solutions tailored to meet your needs. Embrace technology, streamline operations, and pave the way for a more efficient future with the smart use of barcode label ribbons.